Model No.︰ Deposit

Brand Name︰HeXu

Country of Origin︰China

Unit Price︰US $ 5888 / pc

Minimum Order︰1 pc

Automatic Potato French Fries Production Line Potato Chips Making Machine

This processing plant is combined with washing peeling machine, cutting machine, washing soaking machine and spinner machine. The handling capacity is around 200-500kg per hour. Suitable for cassva, yam, carrot and some other root vegetables. The full line can be customized according to your requirement.

The price here is for deposit only. Please kindly contact us to get a latest quotation and more information.

Washing & Peeling Machine

Power: 1.5kw Brush: 800mm * 6 pieces Type: full set of abrasive rollers

* At the bottom of the machine there is a waste collection plate which can be easily disassembled to prevent sewage and dander from contaminating the ground or blocking the sewage outlet;

* There's a waterline on top of the machine so that it can work with/without water;

* Equipped with a cover to avoid splashing.

Chips Cutting Machine

Power: 1.35kw Cutting Size: 0-60mm adjustable

* The cutting speed is fast, there is no damage to the material, and the moisture of the material is kept.

* The cutting size can be adjusted, and different knives can also be used according to the material.

* Adopts waterproof design, conveyor belt and cutter can be washed with water.

Conveyor Machine

Conveyor Machine

Power: 0.25kw

* Made of stainless steel and food-grade conveyor belt.

* Adjustable conveying speed to meet your different needs.

Washing & Soaking Machine

Power: 2.5kw With bubble, ozone and circulating water

* It can not only be used for washing with bubbles and ozone, but also can be used for soaking with clean water.

* Due to the high content of tapioca starch, we specially customized it to be easy-clean-type, which is convenient for cleaning the machine after daily use to prevent starch deposition or odor.

Turntable

Turntable

* This table is put after the washing machine.

* Baskets are put on the turntable to collect the chips from the washing machine.

* Once the basket is full, take it out and put it into the spinner machine for dewatering.

Spinner Machine

Power: 1.5kw Capacity: 10-15kg per batch

* Using frequency conversion technology and PLC touch screen to control dehydration time and dehydration speed.

* Adopts frequency conversion speed regulation three-phase asynchronous motor, which has smooth operation transmission and convenient speed adjustment.

* New upgraded waterproof motor with better effect and longer life.

Finished Products Display

Product packaging

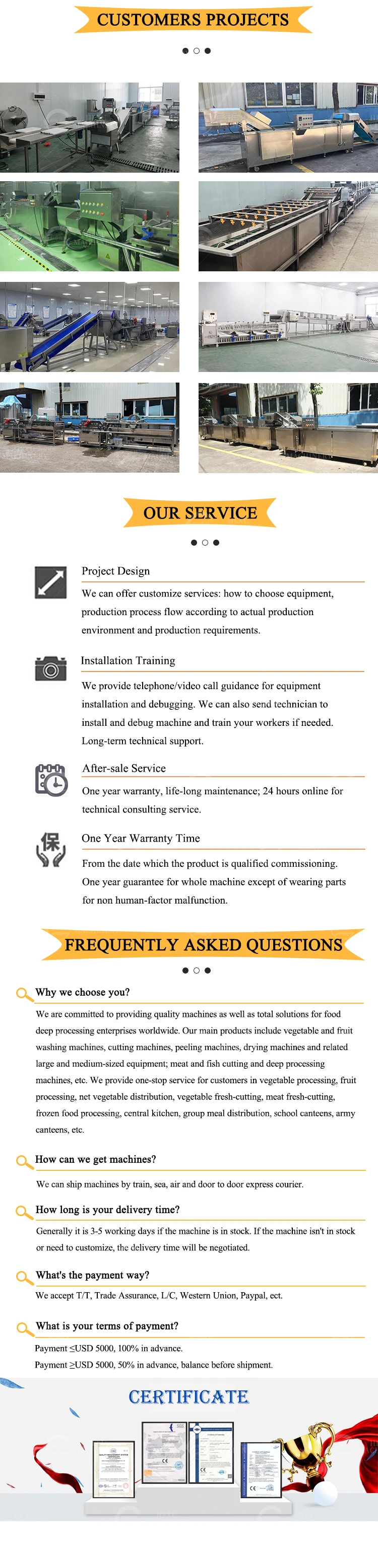

About Us

About Us

Payment Terms︰ TT/LC/Western Union

Packing︰ export plywood case