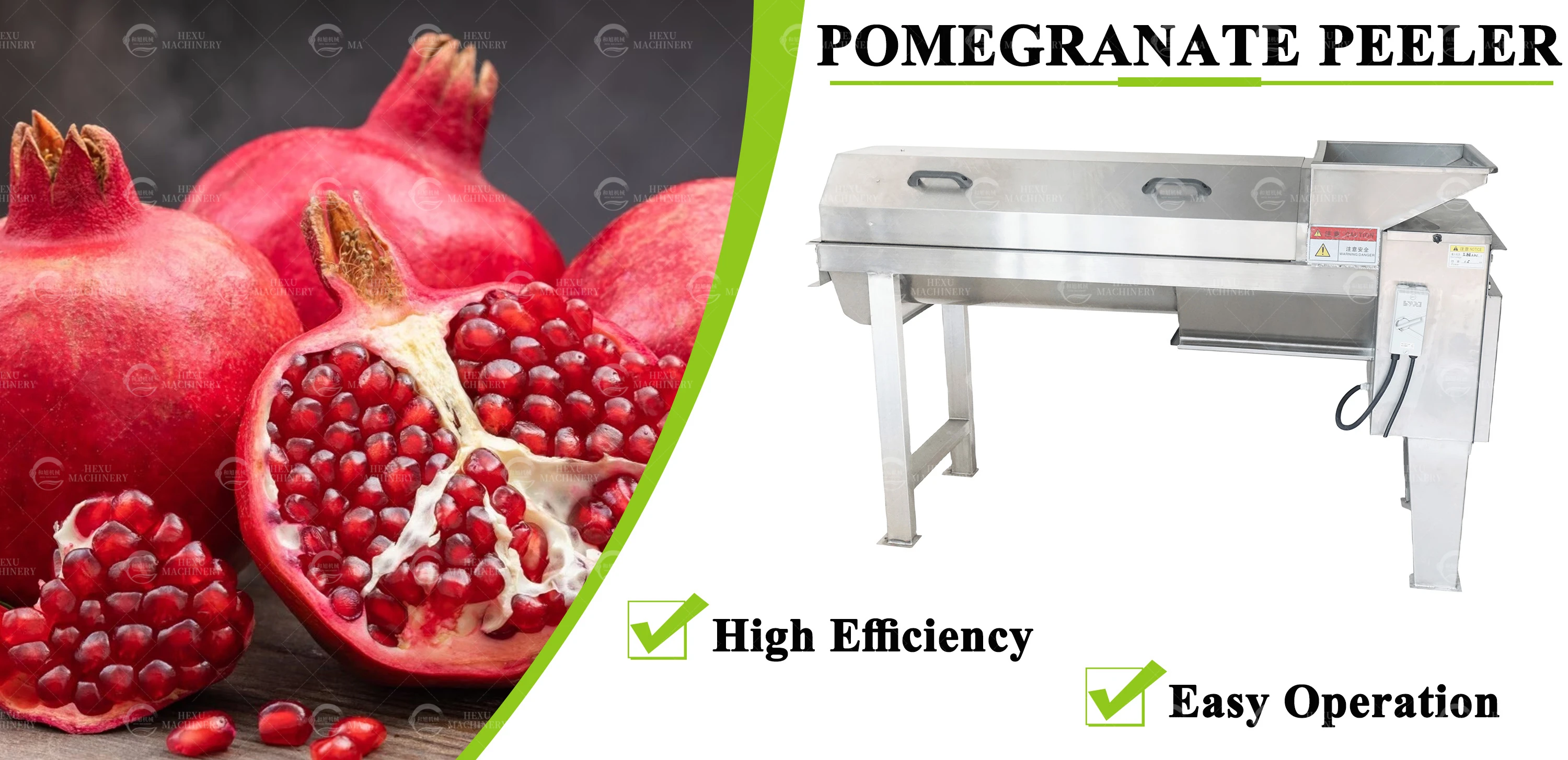

Commercial Pomegranate Peeling Seed Removing Machine

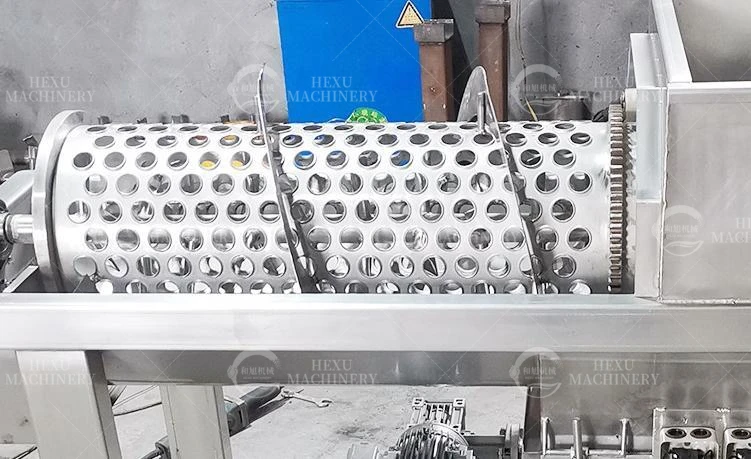

The pomegranate is pushed by the feed hopper through the spiral to the dispersal device. The dispersal device is the spiral shape formed by two fruit bars to disperse the pomegranate. After the dispersal, the pomegranate seeds fall into the guide material through the rotating screen hole, and are transported to the discharge port through the spiral on the rotating screen. The pomegranate peel is pushed to the discharge port at the end of the machine through a spiral formed by the disperser.

Manufacturing Technique

| Model |

QP-101S Pomegranate Peeling Machine |

| Dimension |

1880*615*1165mm |

| Voltage |

220V/380V/customized |

| Power |

1.5kw |

| Rotating Screen |

280mm |

| Mesh Size |

14mm/16mm |

| Capacity |

Max. 500kg per hour |

| Material |

SUS304 stainless steel |

Detail Images

* This machine uses screw to push materials, which is beneficial to material transportation.

* The separated fruits and stems are sieved and the seeds fall out of the mesh.

* The machine is equipped with an enlarged feeding port and is made of stainless steel, making feeding more convenient and safer.

* The machine is available in a variety of different yields. It can be combined with a hoist for continuous production, reducing costs and improving efficiency.

* The machine runs stably, the operation is simple, and the damage to the pomegranate is less.

* The machine adopts pure copper motor with high speed, large power, strong power and stable efficiency.

* The machine is made of 304 stainless steel, and the gap between crushing rollers can be adjusted according to demand.

* The adhesive separation device prevents breakage of the pomegranate.

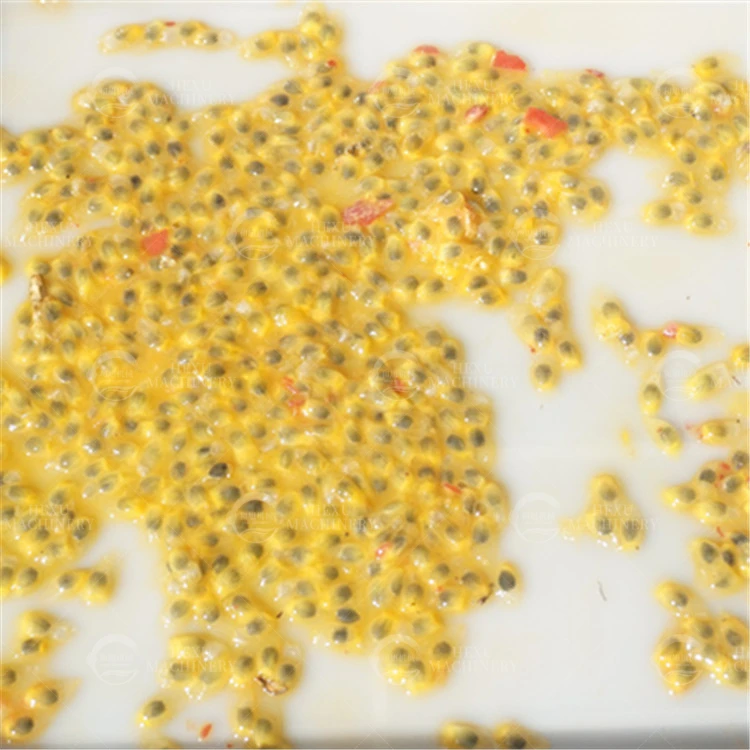

Finished Product Display

Application Scenarios

Product Packaging

About Us