Industrial Orange Apple Tomato Cleaning Washing and Dewatering Production Line

The fruit and vegetable brush bubble washing and drying line is composed of elevating machine, JC-360 brush type cleaning machine, JC-320 bubble type washing machine, JC-350 stepped drying machine and discharging elevator. The production line is suitable for different kinds of vegetables and fruits, with customized output, time-saving, labor-saving and simple operation. It can be used in farms, supermarkets, distribution centers, etc.

The price here is for deposit only. Please kindly contact us to get a latest quotation and more information.

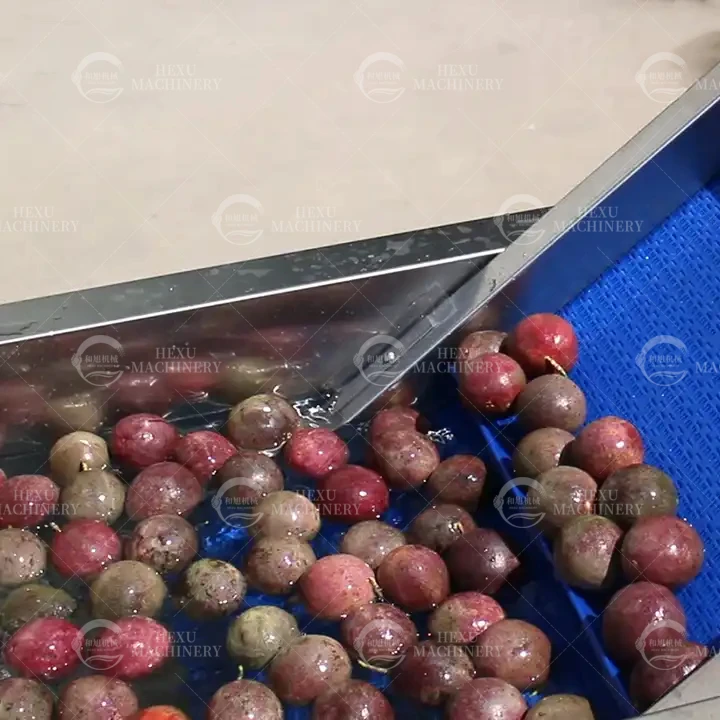

Elevating Machine

This elevating machine with a large hopper is used for soaking and conveying materials.

The machine is made of 304 stainless steel, and the conveyor belt can be made of stainless steel or PP material according to your need. Put the materials into the hopper and soak them in the water to soft the surface dirt, then they will be conveyed to the next process.

Brush Type Cleaning Machine

The materials move forward continuously on the running brushes, and they rubs against the brushes. The dirt, impurities and soil adhered to the materials fall off, and at the same time high-pressure water sprays on the upper part to achieve the purpose of

efficient cleaning. And there is a circulating water tank installed at the bottom of the machine, which is environmentally friendly and saves water.

* It is mainly used for round and oval shapes fruits like passion fruit, lemon, orange, apple, kiwi, sweet potato, tomato, strawberry, blueberry, etc.

* The machine is made of 304 stainless steel and the brushes are rolled with high-quality nylon cord. The brushes type, machine dimension, sprayers can be customized according to the user's production needs.

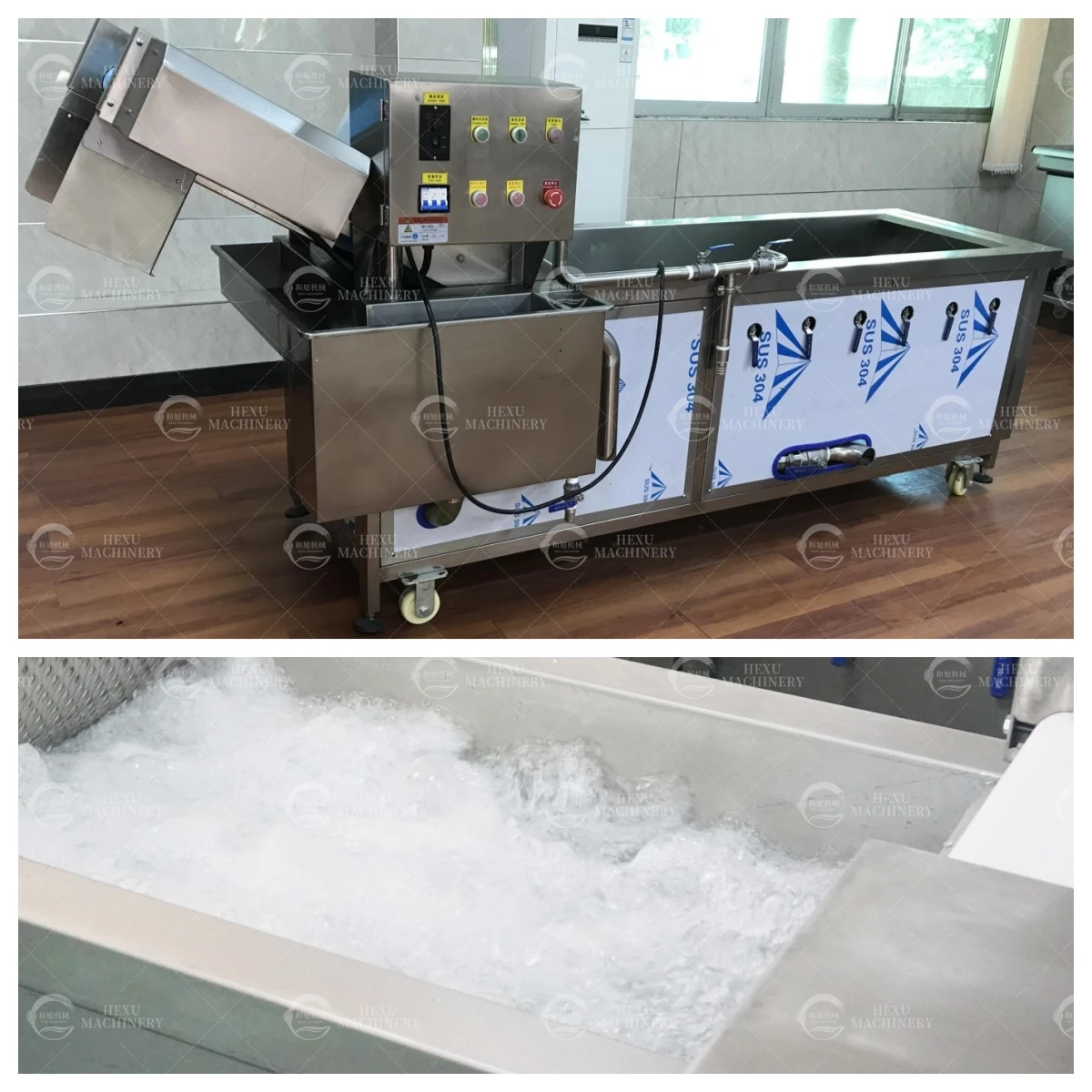

Bubble Type Washing Machine

The ozone disinfection bubble washing machine adopts a combination of three washing methods: bubble, cyclic surfing and high-pressure spray. Through the billowing effect produced in the process of the release of air bubbles, the material in the water has an irregular turnover, effectively clean vegetables without damage. Ozone sterilization and degradation of residual agricultural materials, so that the vegetables can be thoroughly cleaned in all directions.

* A circulating water tank can better filter sediment and impurities, saving water and improving the cleaning effect.

* High-pressure water spraying the materials when conveying to further clean and improve the washing effect.

* The whole machine can be customized according to your production need. According to different materials, we have PP conveyor belt, stainless steel mesh belt and punching hole mesh belt.

Air Blowing Drying Machine

This machine is used for removing the surface water from the washed materials. The stepped mesh belt can turn over the material during the conveying process, so that both sides of the material can be blew. It effectively removes water droplets on the surface of the materials, suitable for assembly line operation, and improves the degree of production automation.

* Being adapted unique air drying apparatus, it makes the air distribute uniform better and guarantee the quality of products is constant. The conveying speed is adjustable.

* According to different materials, we have a variety of fans to choose from: room temperature fans, heating fans, air knife fans and so on. The length of the machine can also be customized according to the output.

After cleaning and drying, you can match different machines according to your production needs:

Dicing Machine

* It dices materials into cube shape in a three dimensional way, making the diced materials quite perfectly.

* Dicing size from 4mm to 20mm optional.

Grading Machine

Grading Machine

* The gap between the rollers gradually increases. During the forward movement, when the fruits reach the position of corresponding size, they fall down on the belt from the gap between the rollers.

Juice Extracting Machine

Juice Extracting Machine

* After the materials enter the machine, they are pressed under the push of the screw, and the squeezed juice flows into the outlet at the bottom through the filter, while the wastes are discharged through the annular gap formed between the spiral and the conical part of the pressure regulation.